Hay hay back with me @jhonmaks, in fact I am very sad today because my previous post titled "How to Make Miniature Planes Using Fiber Glass" is considered to reply writings of others, honestly I am very sad. But after thinking clearly I consider it all the tests that will make me bigger in steemit.

I do not want to dissolve in my grief with a matter as big as this germ hehehe (lol). So today I will keep working with the idea of creative ideas that I pour into a work of my work.

Today I will invite you to make miniature speed boat. So keep reading this article so you can keep up with how to create the miniature. This special writing I addressed to.

- @anomadsoul.

- @acidyo.

- @ocd.

- @hr1.

- @mk40.

- @carbenet.

- @pharesim.

- @dmilton.

- @m31

And special thanks to @thethirdeye has raised my previous writing entitled "Model shipbuilding process", and honestly I hope that this work I write can be read by @curie and all curators in this steemit.

Without extending this article let us continue to see the process of making this miniature.

Miniature speed boat boat is a miniature that is usually for display, speed boat is a machine-powered boat designed to run quickly on water, this ship's miniature is made of fiberglass material, and the advantages of this ship is not easily broken.

For this miniature size alone is.

- Length : 55 cm.

- Height : 8 cm.

- Width : 20 cm.

Before making this miniature we have to get the materials - materials to make a miniature ship sped boat and the materials needed are as follows.

Mate.

Mat is a glass fiber material that is white with irregular arrangement. made of polyester material, Mat serves as a binder. As a result fiberglass becomes strong and not brittle. This met is usually used upon entering the laminate process, this met is usually placed in the first layer after the administration of the sma resin catalyst.

Roving.

Woven roving is tangible like woven with a long fiber group of thick reliefs. Usually packed in the form of a roll of cylinders. Since woven roving is made of two-way continuous glass fibers in a direction between 90 C. Unplanted wovem rovings with resin are strong sheets, which, when drawn primarily from 0 - 90, have a high tensile strength. Usually used on ship tanks or anything big and should be immune.

PVA.

Polyvinyl alcohol (PVA) is a resin made from the incorporation of molecules (polymerization) obtained from the hindrolisis of the vinyl ester polymer using the starting material of polyvinyl acetate. This material is a blue-colored chemical fluid resembling a spirit of barfungsi to coat between mall master or mold with fiberglass material. The objective is that the material does not stick together, so the fiberglass of the printed material can be removed easily from the master mall or the mold.

Resin.

Resins are chemicals that are liquid but rather viscous. Types of resins Miscellaneous Resins are usually used for shapes that accentuate the silence such as: visor accessories, lampshade and others. While darker colored resins are more widely used for the manufacture of accessories. Resin is the main material of fiberglass liner shaped material viscous liquid, clear little red or green. The resin liquid is commonly used by fiberglass docks.

Catalyst.

This liquid is practically a loyal resin companion, this fluid is usually clear and smells stinging. This fluid serves to fasten the process of hardening the dough hardens but the results are not good. This liquid is often called hardener. By definition, the catalyst is a chemical compound that can direct and increase the kinetics of a reaction (if thermodynamically permitted reactions occur). The addition of this catalyst is quite small depending on the type of resin used.

Talk (special flour).

Talc, talc or talcum is a mineral magnesium silicate (hydrated), talc is a natural mineral obtained from talc rock mining. Talc is widely used in the shipping industry is powder for powder.

Cobalt Blue.

Cobalt is a liquid chemical, blue in ink and has an unpleasant smell. This liquid is used to supplement the mixture of the resin & catalyst mixture, so that the dough is more adherent to the meth and accelerate the hardening of the fiber dough too much add cobalt can result in brittle fiber.

This chemical liquid bluish serves as the active ingredient of catalyst mixing to dry quickly, especially when the qualities are poor and too dilute. This material is categorized as a perfect, because not all workshops use it. This depends on the needs of the manufacturer and the quality of the resin it uses.

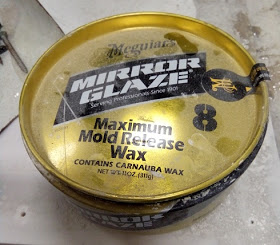

Wax (maximum mold relase wax).

This material is a paste whose function is to coat between mall master or mold with fiberglass material. The goal is that the two materials do not stick together, so the prints can be removed easily. And the color of yellow is usually applied to the fiber maker.

Putty.

Putty is used for uneven and porous surfaces that need to be applied. The goal is that the fiberglass surface of the mold becomes smoother and flat to be ready for painting. The ingredients for making up are: Talk, Cobalt, and Catalyst, then stir until thickened.

Pigment (colourchem).

Pigment is a component of paint making which will give color to the work block so as to give a decorative effect. Pigment in the form of particles of less than 1 micron to 100 microns. Physical form of pigment that is round, flat or needle-shaped.

In the printing world, the pigment is divided into three flat pigments capable of mimicking other pigments when mixed with proper proportions, namely pigmentcyan, magenta, and yellow. In addition to obtaining color depths added black pigment for example to get the sensation of red, mixed with magenta and yellow pigment with a certain proportion.

Gelcoat.

Gelcoat is the material used as the outermost layer of the hull of the ship to be built. Before coated gelcoat, female mold is coated by mirror wax and PVA to facilitate the separation of the stomach formed from female mold. Gelcoat serves to provide a hard layer on the hull of the ship so that the hull is not abrasion.

Gelcoat has almost the same properties as resin but has a greater viscosity value. Gelcoat will coat the outer layer of the hull with a thickness of 0.5 - 0.7 mm and then coated with CSM, this layer is known as skin coat. The outer layer formed from this gelcoat layer usually has a color or pigment to maximize the final layer.

Plywood melamine.

Melaminto or melaminto plywood is part of a plywood coated by a dye. The mixture of materials used is polyester and melamine which are then colored. Melamine plywood has standard thickness, that is 2mm and 3 mm.

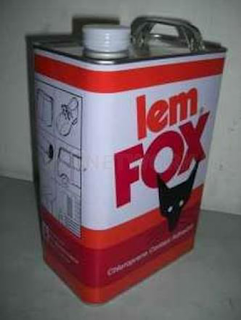

Glue fox.

Glue is a special adhesive material used to attach an object to a particular medium. Yellow glue is also synonymous with wood glue or glue used for wood media. This glue is usually made of vinyl acetate material that is the same basic material with the type of white glue. This glue is highly resistant to wood media, the strong work has rigid properties after application.

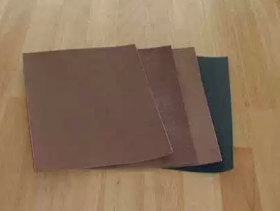

Sandpaper.

Sandpaper is a kind of work tool made of paper or cloth that has been added with a coarse material such as sand grains so sometimes it is called sand paper. Sandpaper serves to make the surface of a rough object becomes more smooth by rubbing its rough surface to the surface of an unfilled workpiece.

There are two types of sandpaper paper along with the level of roughness, namely:

- Coarse sandpaper: starting from 1 to 100.

- Smooth sandpaper: starting from the number 120 to then 100 In sanding process in CV.

Javanese boat usually wear sandpaper no. 120, 240, 320, 500,800 to the last 1000. Kinds and sandpaper functions based on the number:

Extrabrasive sandpaper with a size of 30, 36, 12, 16, sands of this type of sandpaper can be used to smooth a variety of media. Because of its ruggedness, this type of sandpaper is generally used in the early stages in the hard sanding process such as on the terrace wood floor.

Coarse sandpaper with sandpaper size 40, 50, and 60 sandpaper is widely used for sanding purposes with the amount of material removed large.

Sandpaper with medium roughness with the size of sandpaper number 190, 265, 80 sandpaper is usually used when entering the painting position until the final layer finishing sanding.

Very soft sandpaper with sandpaper size 150, 180, 220, this sandpaper can be used to smooth natural wood.

Sandpaper size 360, 320, this sandpaper is usually used to smooth the wood to be polished, for example before polished with wax or wax.

Sandpaper size 800, 1000, 1500, 2000, 2500 sandpaper this function is preferred to polish the polishing layer.

TOOLS - TOOLS USED TO HELP THE MINIATURE SPEED BOAT MAKING

Scissor.

These scissors are made of iron, have a function that is useful for cutting something from the vertical or horizontal direction, scissors there are different types and different models depending on the purpose there are other kinds.

Meter rollers.

The roll meter (pocket gauge / pocket gauge) is a device that acts as a measure of length and distance. This tool can also be used to measure angles, make angles of elbows, and make a circle. The accuracy of the meter rolls up to 0.5 mm.

Screws.

The screw is a rod or tube with a helical groove on its main surface is as a binder to hold 2 objects together and as a simple plane to convert torque into linear force. And the function of the screw itself serves to cheer on the installation of plywood.

Screw drilling machine.

Hand-drilling machine is a drilling machine that operates by hand and shape like a gun,hand drill machine is usually used to punch wood, wall or concrete. The drill machine is also able to tighten the bolt or remove it because it is equipped with two rounds of the right and left.

Circular table machine.

Important parts of the circular table:

Workbench : Place put workpiece to be split. Do not put unused (unnecessary) workpieces on the machine, due to harm when performing and disrupting, putting other workpieces in a separate pallet.

Introduction: Serves to deliver workpiece in the opposite direction with circular saw. This delivery is always angled (angled 90 °) against the work table.

Saw saws: Saws with special eye shapes are designed to cut wood. connected to the driving motor located under the desk.

Knives: Serves to withstand a throwback from a circular saw blade. The distance between the split knife and the outer circle of the saw should be set at a precise distance between 2-4 mm. split blades also work so that the saw blades are not squashed when we split the long wood so that it can reduce the risk of burnt mark on the wood of the cleavage. Knives should be more rendh 3-4 mm from the highest tip of saws so that the workpiece can be smoothly split.

Sawdust: Used as a safety tool and saw blade protection especially when splitting thick wood. This safety should always be placed on top of the saw at the time the engine is run because it also can work to withstand a throwback.

Saw height control: Serves to determine the height of the saw blade according to the thickness of the wood / board to be split.

Angle manager: Adjusts the angle of the saw blades to split the wood with a certain angle of inclination.

Making Speedboat Speed Boat.

Provision of WAX, PVA, and GELCOAT on the miniature hull speed boat.

- Clean the miniature mold until clean does not look dirt / dust.

- Cleaning the wax on the mold as much as 5 times the goal so that when the printout on the loose does not blend with the mold. So that the printout becomes smooth without any basic color is missing.

- Provision of wax by rubbing by using majun / cloth until evenly and to look slippery.

- After being given wax, give pva on the ship mold that has been smeared wax only 1 time.

- Wait until dry.

- Then prepare a mixture of 3cc catalyst, and 5kg gelcoat, mix well.

- Pour the finished mixture into the miniature print.

- Then flatten it using a brush.

- Wait until dry.

Giving of base color on ship hull and ship cabin:

- Gelcoat mixed with 3 cc catalyst and 5 kg coelkut.

- After that stir until blended.

- Then pour the catalyst mixture with the cracker.

- After that then flattened by using a brush.

- When finished wait dry.

- After that it's time to laminate.

Preparation of laminate: (using 450 gauge meth).

- Measure the met throughout the mold.

- Then prepare a mixture of 3 cc catalyst with 0.5 kg resin.

- After the material is ready, then stir until evenly distributed.

- After that pour the catalyst + resin mixture into the container.

- Then apply a brush to a mold that has been given basic color.

- After smeared and give met the size 450, paste on the hull using the mixture.

- At the time of lamination shall be subject to hull angle of the ship.

- After being given 450 metric and mix catalyst and resin, wait until dry. Approximately 1 hour. - Once dry, it's time to remove from the mold, how to use pieces of fiber that is not used.

- After that then flatten the sides - edges evenly. - Then grind the remnants - the rest of the metal to look flat according to its shape.

- Then grind the remnants of the metal using a grinding machine, to look flat according to the fur.

- After the lift from the mold, check if there is less at the time of coloring earlier.

Make floors on miniature speed boat boats:

- Measure the materials that have become fiber by measuring first.

- Measure the middle of the fiber and then make a distance of about 10 cm.

- In the uk, width 22: 2 = 11that mark in the intermediate fiber material between Right + left 11 cm:

UK 2 18: 2 = 9 cm

UK 3 14: 2 = 7 cm

UK 4 13: 2 = 6.5 cm - Once finished, fiber grinding until the object matches the line and forms the base.

Coating parts with fiber material.

- Measure 450 metric metals throughout the mold.

- Then prepare a mixture of 3cc catalyst and 0.5 kg resin.

- After the mixture is ready, apply it to a mold that has been given a jelkoat.

- Then attach the mat and spread with a resin + catalyst mixture.

- After the mat is attached give mat and rub with resin mixture + catalyst.

- Wait until mongering.

- After drying from the mold slowly.

- Then grind the excess.

Creating seat / seat on miniature speed boat + making bulkhead:

- First make the size / bulkhead in the fiber with the size / bulkhead in the fiber with the seat size. - Once the bulkhead has been formed cut into pieces with a grinding machine.

- After that make the barriers in miniature speed boat.

a. Anchoring room.

b. Ceiling glue.

c. Navigation glue.

Installation of glass on miniature speed boat boats:

- Prepare acrylic glass.

- After that then measure acrylic glass.

- Then mark it with a pencil.

- Once marked then cut using grinding machine. - After cut to size, then attach it according to the place.

- Once installed, then give glue G on the sidelines of the glass.

-After the dry glue is given. - After dry and putty by using talk and catalyst, mix and stir until blended.

- Take a little at a time and then apply glass interruptions to appear evenly.

- After the putty then smooth with sandpaper grinding machine.

So that's the tutorial of making miniature speed boat, hopefully this article useful for us all to here the article that I write for today to meet again with other useful articles and greetings from me @jhonmaks.

You've put solid work in this article. I'm wondering what the cost& time are.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

the cost used to make this miniature if you use the dollar is $ 5 usd, and to his advantage is also remarkable, the time to create this miniature if we really take only takes less than 1 hour for 3 miniatures.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit